|

January 31

|

Lyle Solem Moderating |

|

In spite of the below-zero weather, the meeting was well attended. A large number of interesting Show and Tell items took much of the meeting time.

However, Lyle was able to efficiently run us through the favorite jigs presentations that followed, and everybody who brought a favorite jig had an opportunity to

describe theirs and answer questions.

|

|

|

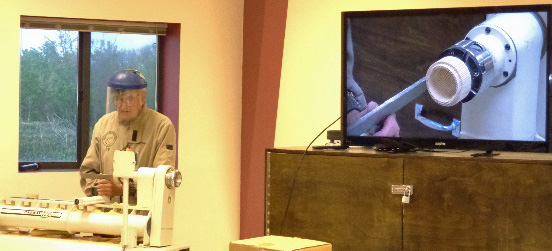

John Thorson demonstrated simple friction-fit wooden discs for reverse-turning bowl bottoms. A headstock-mounted disc grips a bowl from either the inside or the outside of the bowl's lip,

depending on the lip's shape. This is a simple, inexpensive solution compared to a purchased adjustable holder that takes as long to adjust as it does to make a simple disc jig.

|

|

|

Wayne VanEvery epoxies nuts into wooden blanks, and then turns the blanks to make headstock and tailstock fixtures that custom fit his projects. A 3/4"x10 tpi nut

will screw onto most live centers. Using such a nut for tailstock fixtures greatly expands the versatility of the live center beyond the cup and the cones that come with it.

|

|

Click here for Show and Tell Items from the January 31st meeting. |

|

February 28

|

|

|

Wayne VanEvery Presenting |

|

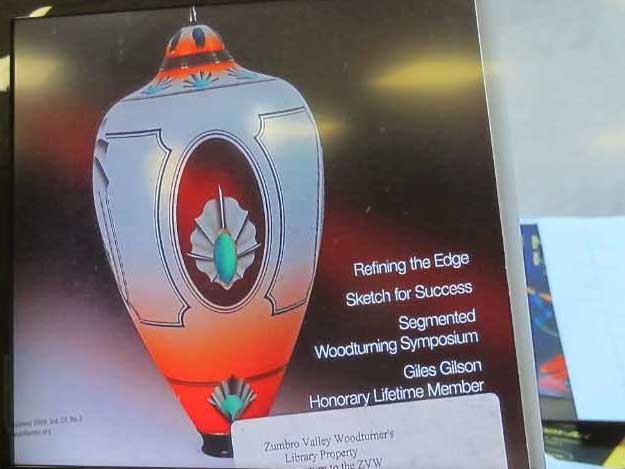

A skilled and imaginative airbrush painter can add a whole new world of artistry to turned forms as show in the example below.

|

|

|

However, airbrush painting skill, like woodturning skill, comes with learning, practice, and of course with the proper materials, equipment and techniques.

|

|

|

This gravity feed airbrush has a single control for air and paint: Push forward for air and downward for paint. This takes skill, but provides a lot of control.

|

|

|

First start with dots. Then go to lines. Practice, practice, practice.

|

|

|

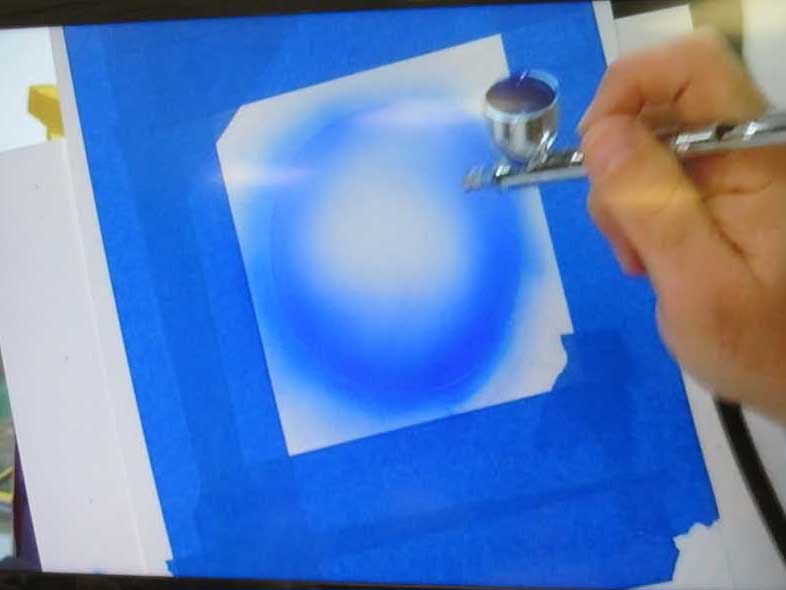

Shading with a mask begins to be more fun.

|

|

|

The result after the mask is removed.

|

|

Click here for Show and Tell Items from the February 28th meeting. |

|

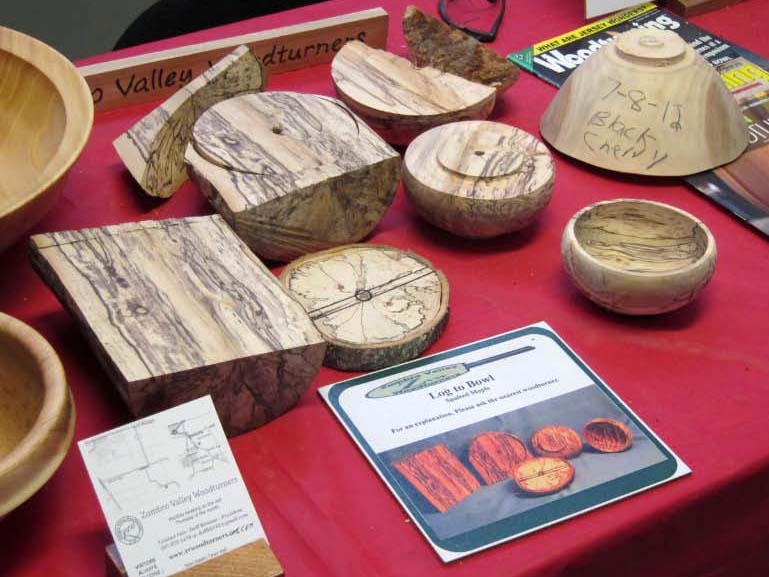

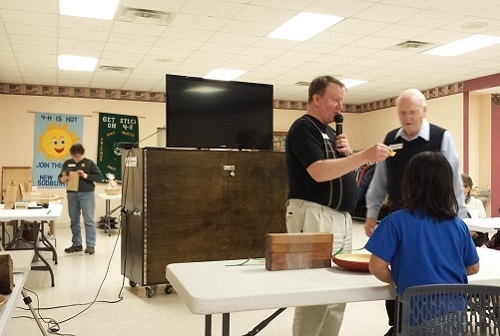

ZVW Displays and Demonstrates at the Rochester Woodcarvers Show on March 23rd and 24th. While Wayne VanEvery was demonstrating turning tops or John Thorson was demonstrating turning bowls, other club members were eagerly explaining how the various items on display were turned and finished.

Todd VanDeWalker and John Thorson manning the table of large bowls.

The demonstration of how a bowl is made from a section of a tree was a popular stop for those curious about how bowls are turned.

Here Jim VanDeWalker is playing with a bowl full of tops made by Wayne Van Every, a turner who prefers to use a skew chisel, a tool that is avoided by many skilled turners .

Lyle Solem is one of the anchor men participating in the show and always has a variety of interesting items to display.

Bob Post's huge multi-wood "waste basket" was perhaps the star of the ZVW display. Visitors stood in line to find out how it was created. |

|

The Rochester Woodcarvers charge no admission for their show, and do not charge their club members to participate. The expenses to produce the show are covered by club-member-donated items which are raffled off at the show. Click here for the 2013 Woodcarvers Show raffle items donated by ZVW. |